Beranda > Program Studi > D-IV Chemical Technology Industry

D-IV Chemical Technology Industry

Tentang Program Studi

The Applied Bachelor’s Program in Industrial Chemical Technology (TKI) at State Polytechnic of Malang (Politeknik Negeri Malang) is a vocational education program equivalent to an applied bachelor’s degree with a 4-year (8-semester) study period. The D4 TKI program has been running since 2015 and is under the Department of Chemical Engineering (JTK). This study program organizes vocational education focused on chemical process technology and constantly adjusts to industry needs. The curriculum is based on the Indonesian National Qualification Framework (KKNI) Level 6, supported by tridharma (three pillars of higher education), competency certification by LSP-P1, and extensive collaboration with domestic and foreign industries and institutions. The Applied Bachelor’s Program in Industrial Chemical Technology has been accredited EXCELLENT by the LAM TEKNIK PII [download certificate], signifying its superior quality in the education system, curriculum, lecturers, and graduates.

VISION

To become an Industrial Chemical Technology Study Program that is Excellent and Globally Competitive in Vocational Education in the Field of Process Technology.

MISSION

- To conduct Diploma IV (Applied Bachelor’s) education to produce excellent, competitive graduates who are ready to professionally apply Chemical Engineering principles highly relevant to the chemical industry.

- To conduct innovative and productive Industry-Oriented Applied Research that genuinely contributes and potentially gains recognition from the chemical industry.

- To carry out Community Service through service and responsibility to the community and industry by acting as a source of skilled education and technology appropriate to the needs of the global era.

- To implement a Diploma IV Education Management System based on the enforced Governance standards.

- To develop mutually beneficial cooperation with various parties both Domestically and Abroad in fields relevant to Chemical Engineering.

GOALS

- To produce graduates with excellent academic capabilities in the process of designing systems and equipment to yield value-added products using existing references and standards, and by considering technical standards, performance aspects, and health, safety, and environmental factors (HSE).

- To produce National, Regional, and International Level Applied Research that is beneficial for the Development of Science, Technology, Business, and Industry, and leads to the achievement of Scientific Publications, Patents, and Intellectual Property Rights;

- To carry out National Level Community Service through the development of Science and Technology and service to the community and industry.

- To produce a Diploma IV Education Management system based on the enforced Governance standards.

- To generate forms of domestic and foreign cooperation relevant to the field of Chemical Engineering.

Kompetensi Lulusan

Graduates of the Applied Bachelor’s Program in Industrial Chemical Technology are expected to possess the following competencies, defined as Graduate Learning Outcomes (GLOs):

| 1 | CPL1: | Able to identify and apply fundamental knowledge of mathematics, physics, environmental science, statistics, and relevant engineering to convert raw materials into value-added products through physical, chemical, and biological processes to support the field of industrial chemical technology. |

| 2 | CPL2: | Able to identify, investigate, and review problems in the field of industrial chemical technology, manage relevant data, and design experiments to solve technical problems through practical application, simulation, research literature, and appropriate analytical methods that can be scientifically proven. |

| 3 | CPL3: | Able to design systems, components, or processes to solve technical problems in the field of Industrial Chemical Technology while considering HSE (Health, Safety, and Environment), materials, culture, social, and environmental issues. |

| 4 | CPL4: | Able to explain the results of tracking, selecting, and organizing appropriate data from codes, databases, and literature, and able to design and conduct experiments to generate and present valid conclusions to address problems in the field of Industrial Chemical Technology. |

| 5 | CPL5: | Able to explain the results of measurements, analyses, and experiments by utilizing resources, technology including prediction and modeling, for problems in Industrial Chemical Technology, considering HSE, legal, social, and cultural issues in an effective presentation. |

| 6 | CPL6: | Able to analyze and evaluate the sustainable impact of Industrial Chemical Technology in solving engineering problems, including energy efficiency, waste management, and its impact on HSE, environment, social, and economy. |

| 7 | CPL7: | Able to demonstrate attitudes and character that reflect: obedience to God Almighty, ethics and integrity, noble morals, concern for social and environmental issues, respect for cultural diversity, upholding the law, prioritizing the interests of the nation and society, possessing creativity, innovation, excellence, and strong leadership abilities, all synergizing based on existing potential for maximum results. |

| 8 | CPL8: | Able to work effectively individually or in teams, applying engineering management principles efficiently in the field of Industrial Chemical Technology based on applicable work competence in the form of reports, final projects, learning activities, or professional cross-disciplinary collaboration results within industrial and research settings, stated logically, innovatively, and measurably with consideration for occupational health, safety, and security. |

| 9 | CPL9: | Able to apply written, verbal, and visual communication effectively and inclusively, paying attention to cultural, language, and learning differences, so that the message is understood within their community and the general public. |

| 10 | CPL10: | Able to apply knowledge of engineering management principles to work performed in group activities as a member or leader managing the field of Industrial Chemical Technology. |

| 11 | CPL11: | Able to analyze and develop the importance of lifelong self-learning and apply it to be competitive nationally and internationally, and apply critical thinking to evaluate problems and find innovative solutions in complex technical and professional situations. |

Alumni Prospects

Graduates of Industrial Chemical Technology from State Polytechnic of Malang emerge as leaders in various fields and professions. They become inventors, entrepreneurs, educators, researchers, and executives. Generally, they hold positions in the chemical and energy industries, biotechnology, pharmaceuticals, electronic device manufacturing, and various material-related industries.

Profil Lulusan

After completing the education in the Applied Bachelor’s Program in Industrial Chemical Technology, graduates possess the following INDEPENDENT PROFESSIONAL PROFILES (IPPs):

| PPM1 | : | Industrial Chemical Technology Professional with deep expertise in process and equipment evaluation; process system design, and possessing a strong ability to analyze and evaluate the sustainable impact of the designed processes, particularly in the food, fuel, and environment sectors (F2E). |

| PPM2 | : | An Individual who has the ability to pursue lifelong learning through further education, research, and professional development to maintain and enhance expertise in industrial chemical technology, especially in the F2E sector. |

| PPM3 | : | A Professional or Entrepreneur who is capable of demonstrating ethical responsibility, teamwork, and leadership, and can contribute positively to overcoming societal and professional challenges by upholding industry standards, codes of ethics, and applicable regulations. |

Peluang Kerja

Graduates of the Applied Bachelor’s Program (D4) in Industrial Chemical Technology have a wide range of career opportunities, including as a Process Engineer in the chemical and petrochemical industries, Quality Control (QC) and Quality Assurance (QA) Officer, Research and Development (R&D) Staff, Operator or Technician in Chemical Plants, Health, Safety, and Environment (HSE) Consultant, Entrepreneur (Technopreneur) in the chemical industry, or as a vocational educator and laboratory analyst.

To support and ensure graduates are ready to face these career opportunities, the D4 TKI Study Program has committed through various strategic steps, such as developing a curriculum based on the KKNI (Indonesian National Qualification Framework) and industry needs, implementing a project-based learning method to develop both hard skills and soft skills in every student. A learning ratio of 60% practical and 40% theoretical serves as the main foundation, promoting the concept of learning by doing. Furthermore, we establish cooperation with various national and international companies, provide internship and industrial practice programs (Teaching Factory), and invite guest lecturers from practitioners. In addition, students are equipped with national competency certification from LSP-P1 Polinema, which is licensed by BNSP, and receive training in soft skills, technopreneurship, and professional communication essential for the workplace. The D-IV TKI Study Program also regularly conducts tracer studies and graduate user satisfaction evaluations to continuously enhance the quality and relevance of its graduates in the industrial world. Coupled with complete laboratory facilities, professional lecturers, and a curriculum that is up-to-date with industry needs, we are confident that the graduates will be optimally prepared to face industrial challenges.

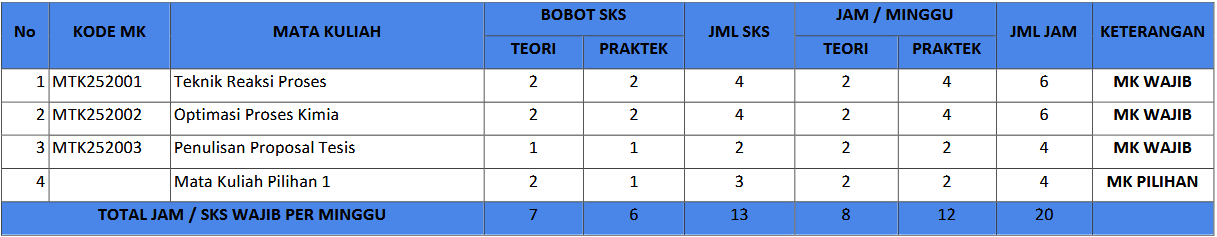

TAHUN AKADEMIK 2025/2026

Kurikulum Tahun Ke-1

Kurikulum Tahun Ke-2

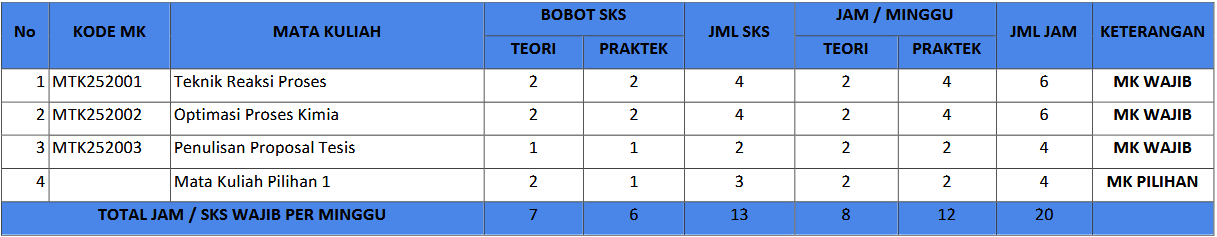

Mata Kuliah Pilihan

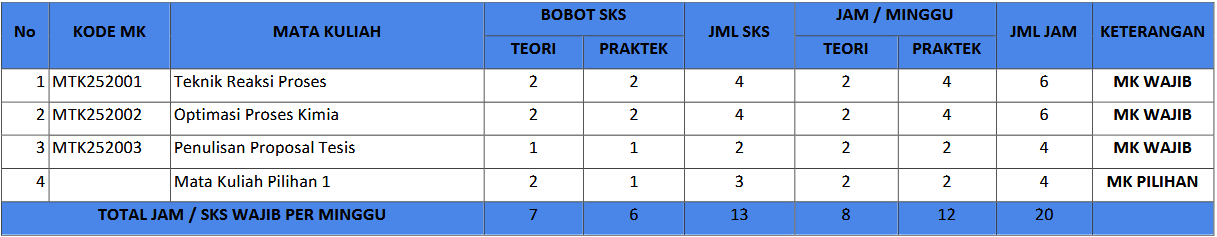

Tahun Akademik 2024/2025

Kurikulum Tahun ke-1

Kurikulum Tahun Ke-2

Mata Kuliah Pilihan